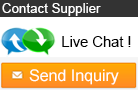

JASU H-800 Moveable Column Horizontal CNC Machining Center

Product Description

Advantages:

1.Machine base is T shape, which connects directly with worktable. Worktable moves in Z axis only so it has better dynamic loading capacity and better precision stablity.

2.The linear guides of X axis are placed in ladder shape. So column can better resist the direct shock force from machining.

3.Headstock is at front side of column, it is very suitable for large hole deep drilling machining of box shaped parts.

JASU H-800 Horizontal CNC Milling Machine is JASU patented product. The worktable can incorporate a precision rotary table, it can index freely with high accuracy and repeated positioning accuracy. It features heavy duty cutting and achieve 4 axes coordinated machining. The work piece can be clamped at one time to finish milling, drilling, boring and reaming machining etc at four faces.

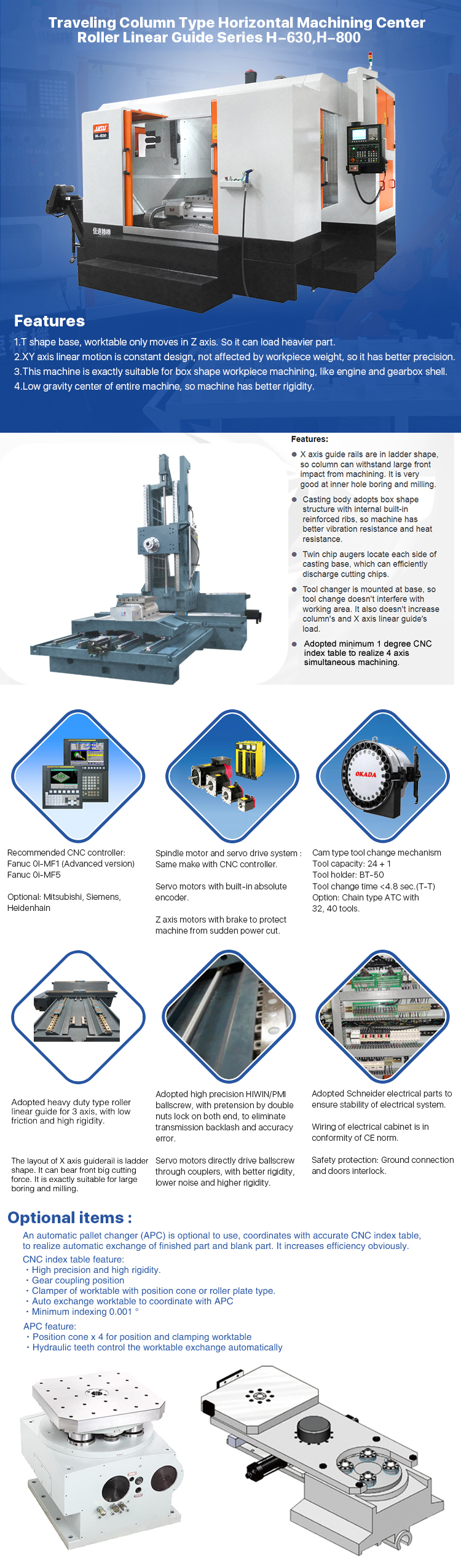

Specification of H series

| Specification | H-800 |

Worktable | Pallet Changer (Opt.) |

| Worktable size | 800 x 800 mm |

| Min. Index degree | 1 or 5 deg. |

| Index accuracy | 5 sec |

| Repeatability | 1 sec |

| Max. loading capacity | 3000 kg |

Travel | |

| X/Y/Z axis travel | 1400/1000/1000 mm |

| Spindle center to table | 110-1110 mm |

| Spindle end face to table center | 220-1220 mm |

Spindle | |

| Spindle taper | BT50 |

| Max. spindle speed | 6000 rpm |

| Drive method | Belt drive |

| Spindle motor power | 11/15 KW |

Feeding | |

| XYZ axis cutting feedrate | 1 -4000 mm/min |

| XYZ axis rapid traverse | 24 m/min |

| XYZ servo motor power (Fanuc) | 3/3/3 KW |

| Ballscrew spec. | Ø50-P10 |

| Positioning accuracy (JIS) | ±0.003/300 mm |

| Repeatability (JIS) | ±0.003 mm |

| ATC | |

| ATC type | Arm type |

| Tool capacity | 24 pcs |

| Max. tool dia. x length | 120 x 300 mm |

| Max. tool weight | 15 kg |

| Tool change time (T-T) | < 3.8 sec |

| General | |

| Coolant motor | 0.49 KW |

| Air required | 8 KG |

| Power capacity | 30 KVA |

| Overall dimension | 4.6 x 2.6 x 3.6 m |

| Net weight | 14000 kg |

Standard and optional configuration

Standard configuration | Optional configuration |

1.Fanuc/Mitsubishi/Siemens CNC controller 9.Arm type ATC T24 11.Working light | 1.Chain type ATC-T32/T40 2.Chain plate type chip conveyor and chip cart 4.Direct spindle BT50-8000rpm 5.Spindle gearbox 7.NC rotary table

|

Email to this supplier